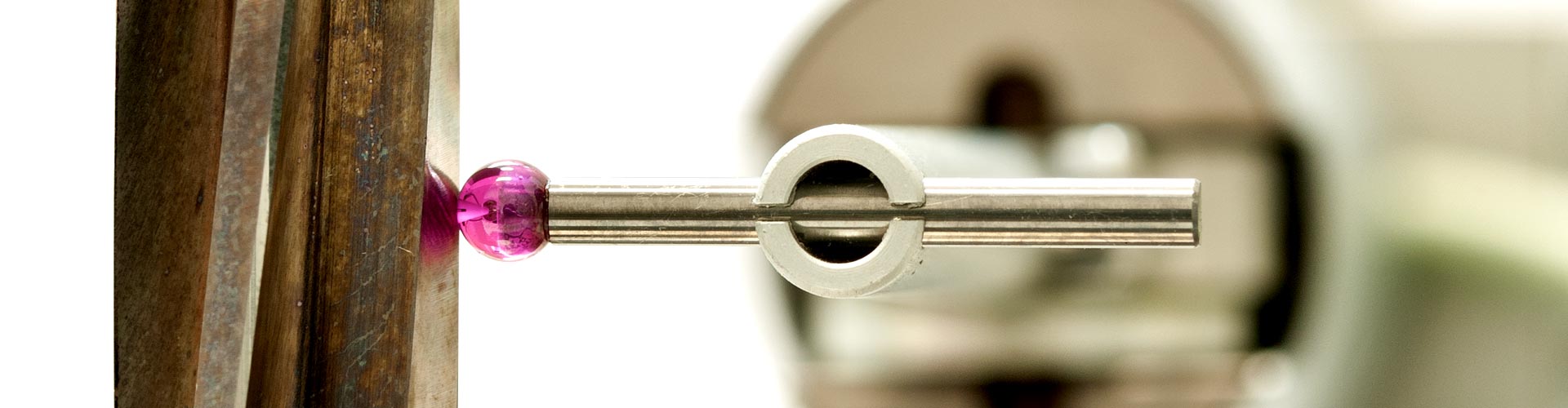

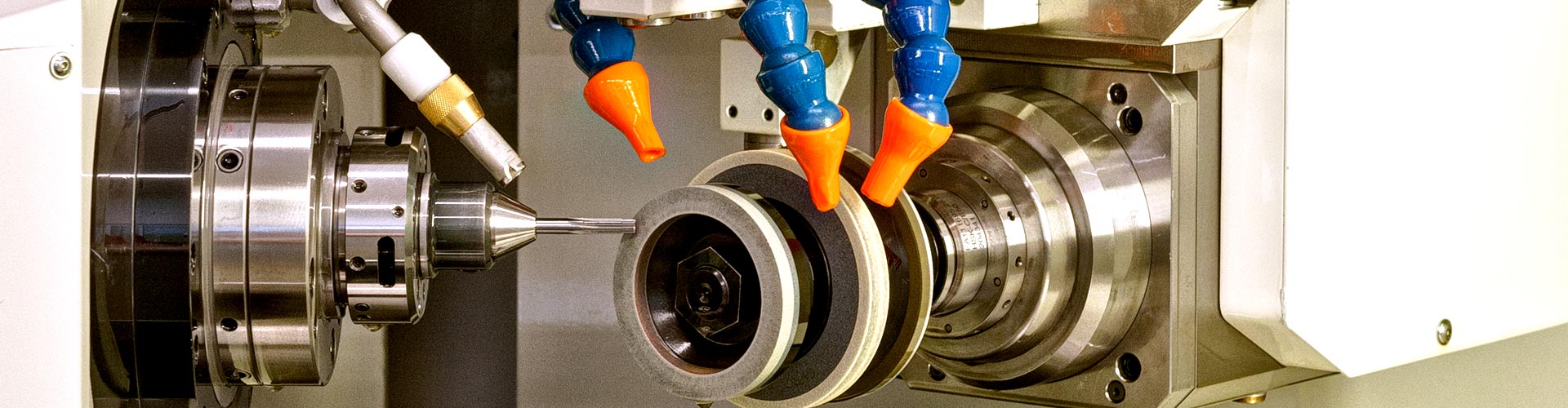

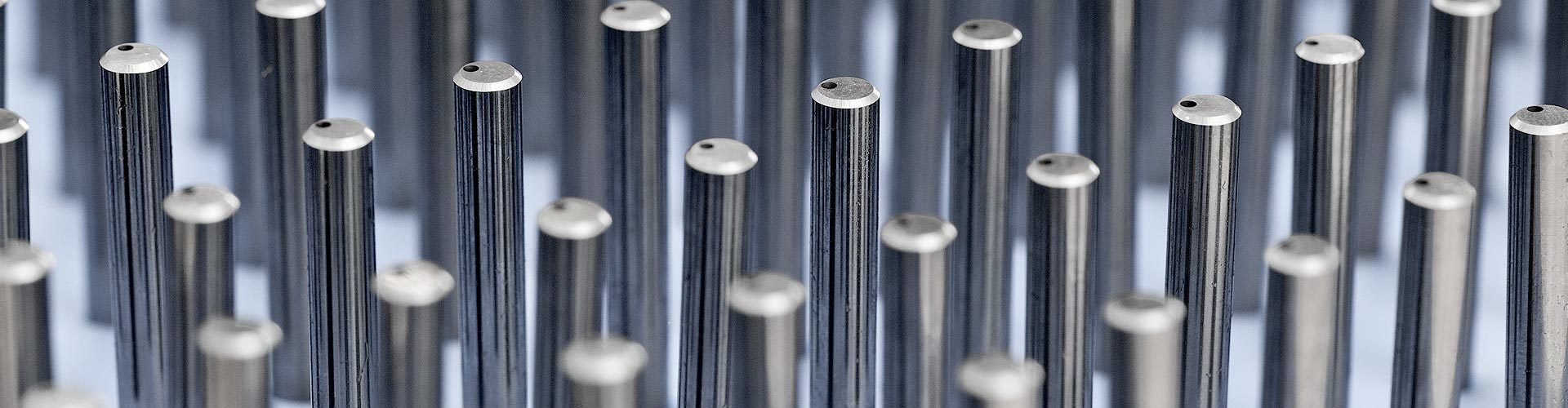

Hobe GmbH is a southern German manufacturer of precision tools for the shaping of interior profiles in very small bores. We develop, manufacture and distribute high-quality micro-tools made of solid carbide for the machining of sophisticated metal and plastic components. Since the company was founded in 1971, we have applied ourselves with enthusiasm to innovative tool technology and continue to push the boundaries of possibility every day. Read more ...

Innovative tools, applied efficiently. This is our successful formula for outstanding cutting results. We have the development skills for standardised and technically advanced tool systems, as well as the special expertise for individual industry solutions which deliver maximum efficiency and economy. Clients across diverse industries appreciate our comprehensive services for high-precision turning, drilling, boring and milling to produce complex internal profiles and the finest threading. Discover our tools ...

Standard tools

Do you know which tool you need?

Order online from our extensive range of standard tools, offering a variety of coating and customisation options.

Special tools

Would you like to customise a particular tool to meet your specifications?

Just fill out and submit our inquiry form for custom tools. We will get back to you as soon as possible.

Services

Are you seeking a comprehensive tool and process solution for your application?

Let us assist you with our extensive consulting, development and production expertise.

Rainford Precision represents Hobe micro tools at the MACH2024

Rainford Precision represents Hobe micro tools at MACH 2024 in Birm...

New product catalogue

The new product catalog is here! In the new 148-page glossy brochure, our...

New Partnership in the USA

New Partnership in the USA! We are proud to announce that Full...

Micro Bores Portfolio 2024

New Drill Bits! Finally the time has come! We are pleased to present yo...

Sustainability is more than just a promise!

Sustainability is more than just a promise - At Hobe we act! ...

ISO 9001:2015 Certificate till 2025

Sucsessful re-certification Our new ISO 9001:2015 certificat...

Product innovations at the AMB

Our suitcases are packed! - The countdown is running. Only a few day...

MedtecLIVE with T4M 2022

Successful start of the new trade fair MedtecLIVE with T4M : Wi...

Guide to German Medtech Companies 2022

Medical technology is getting back on track Hobe GmbH is represented in the ...

50 Years Hobe GmbH | micro tools

We celebrate our 50th anniversary! We turned 50 on July ...

Hobe Information Brochure

Innovation results from motivation at Hobe | Micro Tools We...

Hobe in medical technology and implantology

NEW Version - more applications! Medical devices/pro...

New Processing Examples

After updating our website a few weeks ago we supplemented some ...

Dreh- und Spantage Villingen-Schwenningen 2019

The Dreh- und Spantage (DST) 2019 ended successfully last Friday....

INTEC Leipzig 2019

The INTEC 2019 trade fair came to a successful end on Friday: 24,40...

3D-Tool Data - Fit for industy 4.0!

A CAD/CAM simulation of component machining is in many cases inevit...

Deutsch

Deutsch

English

English

Französisch

Französisch

.jpg)